Bruxelles Environnement

Context

Belexpo is an exhibition, by Bruxelles Environnement, about the environment, the city and the climate. It is mainly addressed to children from 10 to 14 years old.

This exhibition is highly interactive, very successful, and thus challenged and worn by its many mini-visitors.

For an ultimate experience of the exhibition, the visitors are given a watch to go over their wrists and that activates the many challenges of the exhibition. The watch allows the interaction between the visitors and the elements of the exhibition and is a crucial tool for Belexpo.

Bruxelles Environnement has witnessed a rapid degeneration of the bracelets holding the watches and could not access space parts to replace them with. Not that the replacement would have been smooth anyway. We have been asked to look into this problem, analyse it, and research to find a solution that listens to the needs of both the user and the staff handling the product everyday. The brief is to develop new bracelets for the watches of Belexpo

Product specifications

Adjustable

Easily fixed around the wrist

Respects hygiene conditions/ easily cleanable

Sustainable, long lasting, and easily replaceable.

Work in Progress

We have put together a product in progress that is manufactured in Brussels, partially by us, HIER, and partially by our recurrent collaborator, L’Ouvroir.

L’Ouvroir is an association located in the heart of Brussels. It is an initiative carried by people with disabilities wanting to be engaged and participate in their society. Together, despite their disabilities, they built a workshop where they undertake varied manual/productive activities.

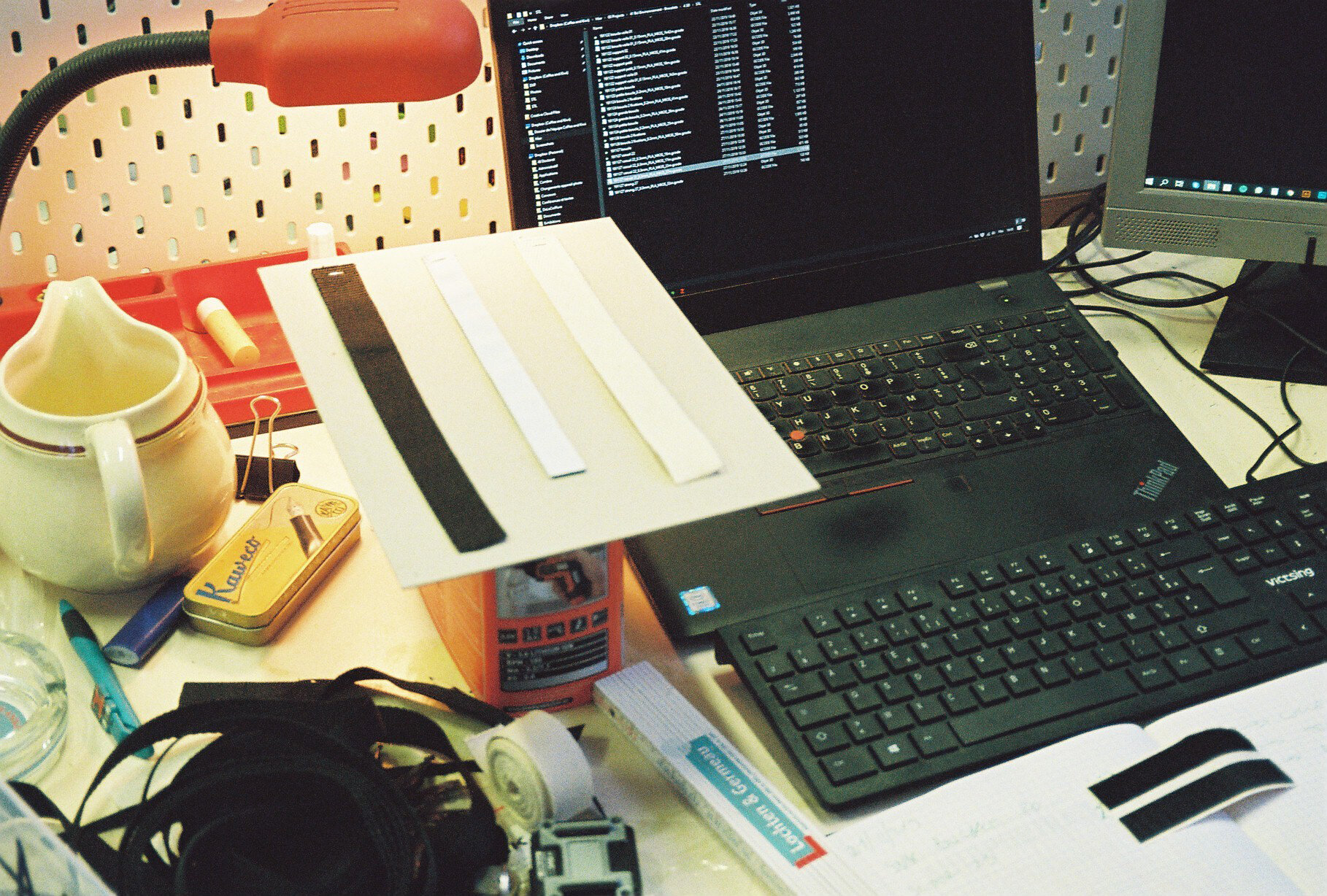

They are producing the fabric part of the bracelet while we are modelling and 3D printing the details adapting to the existing watch and holding together the fabric bracelet.

For the fabric part of the bracelet, we chose Nylon. A recyclable strong plastic, resistant, and cleanable by machine. We have designed the 3D printed details in a way that allows the team to easily remove the nylon bracelet and clean it in a washing machine. This nylon bracelet has a Velcro sewn on it by l’Ouvroir making the bracelet easily fixable around the wrist of both an adult and a child; the velcro making the whole adjustable.

For the 3D printed parts, we have chosen to work with PLA which later becomes an industrial compost, recyclable. We have printed these parts in 5 different colours to facilitate recognising the charged watches from others. Those 3D printed parts are easily mountable and replaceable, making their maintenance smooth.

The design is adaptable, adjustable, and efficient. We chose to concentrate the production in Brussels, to make sure that the products are easily reproduced or repaired without any need for costly maintenance equipment. We have listened to the needs of our client, Bxl. Env., worked on different options, together with them and l’Ouvroir, to come up with this version of the product in process; the fruit of our triangular collaboration.

More information about:

Belexpo or Bruxelles Environnement